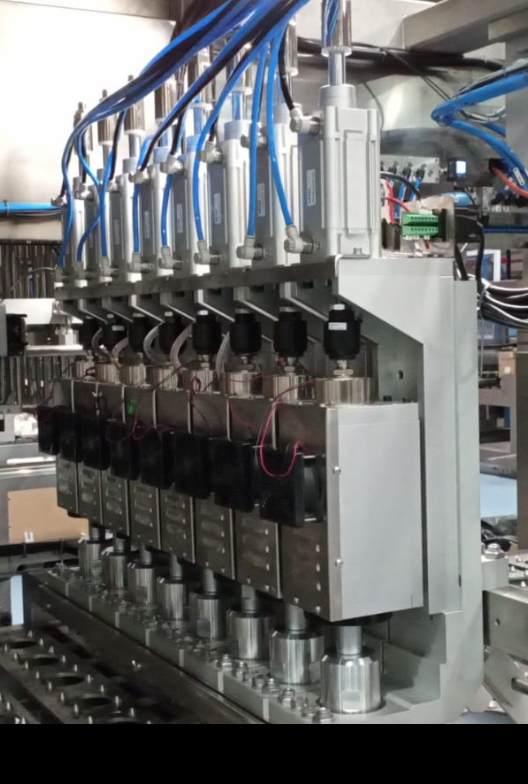

Advanced 20Khz Ultrasonic Daily Necessities Welding Machine for Plastic

20Khz customized ultrasonic welding machine ultrasonic welding plastic

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

Deccription

With the rapid development of the material industry, the application of plastics and metal composite materials with light weight, low friction, corrosion resistance and easy processing has attracted people’s attention. Various plastic products have penetrated into various fields of people’s daily life, and are also widely used in aviation, ships, automobiles, electrical appliances, packaging, toys, electronics, textiles and other industries. However, due to the limitation of injection molding process and other factors, a considerable number of plastic products with complex shapes cannot be injection molded at one time, which requires bonding. However, the plastic bonding and heat sealing process that has been used for many years is quite backward. Not only is the efficiency low, but also the adhesive has certain toxicity, causing environmental pollution and labor protection problems. This traditional process can no longer meet the development needs of the modern plastics industry. . So a novel plastic processing technology——ultrasonic plastic welding stands out for its advantages of high efficiency, high quality, beautiful appearance, energy saving and so on. When ultrasonic welding is welding plastic products, it does not need to add any adhesives, fillers or solvents. , does not consume a large amount of heat source, has the advantages of simple operation, fast welding speed, high welding strength and high production efficiency. Therefore, ultrasonic welding technology is more and more widely used. But not all plastics can be ultrasonically welded. Most of the materials suitable for ultrasonic welding are thermoplastics. It is a polymer that can soften and flow when heated, and solidify when cooled. It can be repeated many times without changing its chemical structure. thing. Thermosetting plastics cannot be ultrasonically welded.

What are the methods of ultrasonic welding?

ultrasonic forming

Similar to ultrasonic riveting. It is to press the concave welding head on the outer ring of the plastic product, make it vibrate at high frequency, then melt the plastic and wrap it on the metal object to fix it, and the appearance is smooth and beautiful. It is mostly used in the fixing and forming of electronics and speakers. And lens fixation for cosmetics, etc.

Ultrasonic Implantation

Ultrasonic ultra-high-frequency sound wave vibration, through the conduction of the welding head and appropriate pressure, instantly squeeze metal parts (such as nuts, screws) into the reserved plastic holes, and fix them at the set depth. After completion, regardless of the tension and torsion, the strength of the traditional molding in the mold can be compared, and the shortcomings of damaged and slow injection can be avoided.

Ultrasonic riveting

Press the ultrasonic ultra-high-frequency vibration welding head against the protruding tip of the plastic product, making it instantly heat and melt into the shape of a rivet, so that the metal object is riveted and fixed.

ultrasonic spot welding

When two pieces of plastic are to be welded, due to the limited conditions of the welded material, it is impossible to set up a fuse line, and spot welding can be used for welding. The principle is to use ultrasonic waves to transmit to the front of the welding head, and pass through from the upper plate to the lower plate to achieve the effect of welding. And it can spot weld multiple points at the same time to improve work efficiency.

Ultrasonic resection

The ultrasonic high-speed vibration welding head cuts off the sharp burrs of injection-molded plastic parts, and cuts off the injection port, so that the plastic parts are separated from the injection flow channel in an instant, eliminating the need for manual removal. Materials suitable for ultrasonic resection include ABS, PS, acrylic, PC, plastic steel, etc. Plastics that are too soft or elastic are not suitable for ultrasonic resection. (The effect is not good if the plastic material is not cooled when it is just injected

Designed with user efficiency in mind, our Ultrasonic Daily Necessities Welding Machine simplifies the complex process of ultrasonic welding, reducing operational downtime and increasing productivity. The advanced technology ensures minimal maintenance, extended lifespan, and superior performance, making it an indispensable tool for manufacturers seeking high-quality welding solutions for plastic daily necessities. Integrate this machine into your production line and experience the unparalleled benefits of precise, efficient, and reliable welding. By choosing our ultrasonic welding machine, you are investing in a product that stands at the pinnacle of technological advancement in the field of plastic welding. Embrace the future of manufacturing with our expertly crafted ultrasonic welding solution, engineered for optimum performance and exceptional results.

Q1.What kind material of the horn?

A. Titanium alloy, we also customized aluminum hom for customer before.

Q2.What’s the time of delivery?

A. For Conventional hom, 3 days, for customized hom 7 work days.

Q3.Does ultrasonic extraction also require the addition of a chemical catalyst?

A. No . but some time need Mechanical stiring.

Q4.Can the device work continously?

A. Yes ,it can work 24hours continously.

Q5.What’s the Processing capacity of one set ultrasonic extraction equipment?

A. Different hor different Processing capacity, for 2000W Nine section whip horm can dealing 2L~10Lmin.

Q6.What’s the warranty of your sonicator equipment?

A. All equipment one year warranty.